IATF 16949 and What It Means in PCBs

Sponsored Post from NextPCB

PCB manufacturers often present their customers with an IATF 16949 certificate on top of known certifications such as UL and ISO. What is this certification and why should we care about it?

IATF 16949:2016 is a standard that establishes the requirements for a Quality Management System (QMS), specifically for the automotive sector. Moreover, it is meant to be a supplement for ISO 9001 standard which defines the base requirements for QMS.

What is QMS?

I think it’s hard to discuss IATF 16949 without discussing what QMS is. As already mentioned, QMS stands for Quality Management System and is written in a set of documents provided by the International Standards Organization. A company with QMS follows well-defined procedures to maintain high quality products and establish a good relationship with its customers.

QMS follows the so-called Quality Management Principles:

- Customer focus

- Leadership

- Engagement of people

- Process approach

- Improvement

- Evidence-based decision making

- Relationship management

While these points might be vague, the ISO:9001 defines a concrete set of procedures to ensure that these are achieved by the company.

IATF 16949 and PCB Production

ISO 9001 extends to all types of organizations, private or public. IATF 16949 is a set of standards that apply specifically to the automotive sector.

The IATF 16949 was established in 2017 as a replacement for ISO 16949. Those companies who directly or indirectly work with automotive production aims to follow this standard. Since vehicles now have electronic components, its PCBs should also follow a strict set of product quality guidelines.

In a nutshell, IATF 16949 provides means for a company to identify and minimize the risks in all facets. All this while meeting (if not exceeding) all customer and organizational goals and objectives.

Ok, so what if a PCB manufacturing company has this certification? What does it mean for a customer like me?

This means that the PCB manufacturing company strictly provides the following:

- Ensures that their PCBs consistently meet customer requirements as well as all applicable statutory, regulatory and product safety requirements

- PCB customers first and satisfaction mindset

- Believes in continuing improvement of their PCB manufacturing system

- Make PCB customers loyal and thus order again

- Identify and address the risks associated with PCB production

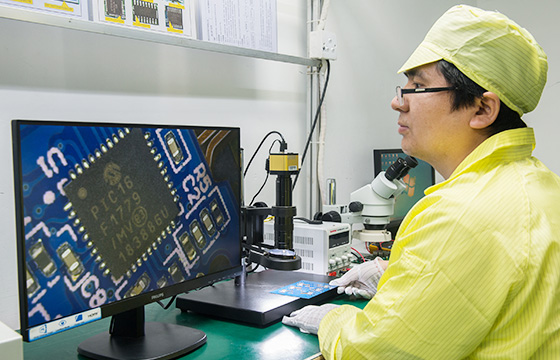

NextPCB is a PCB manufacturing company that has an IATF 16949 certification. This means it is a company that implements continual improvement, defect prevention and reduction of variation and waste in the supply chain. As such, expect only the highest quality of PCBs from this company.

About NextPCB

NextPCB is one of the most experienced PCB manufacturers in China, and has specialized in the PCB and assembly industry for over 15 years. Not only could NextPCB provide the most innovative printed circuit boards and assembly technologies in the highest quality standards, the fastest delivery turnaround as fast as 24 hours, the lowest manufacturer direct prices, and the most dedicated customer service in the industry, but NextPCB could also provide turnkey service without a broker including components sourcing, PCB prototyping/PCB manufacturing, PCB assembly, quality testing, and the final shipment. Certainly, NextPCB could meet your needs from PCB prototyping to small PCB production or mass PCB production.

Address: Room503, Tianxin Building, Meilin Street, Futian District,

Shenzhen, China , 518000

E-mail: support@nextpcb.com / service@nextpcb.com

Skype: nextpcb@outlook.com

Tel.: +86-755-83285752