Seeed Studio now Offering Free DFA Review for PCBA Orders

This post is sponsored by Seeed Studio

With a focus on giving customers the best value for money, Seeed Fusion’s turnkey PCB assembly now offers free Design for Assembly (DFA) on all PCB assembly orders. This is supposed to be the first on a series of new offers Seeed Studio will be rolling out every month of this year and maybe, beyond.

A DFA feature is surely enticing for electronic designers but giving it FOR FREE with PCBA order is something else. Seeed Studio claims that the old fees for PCBA are retained and no additional fees were added. Of course, I had to check that out for myself and it’s true. The service is valuable and I presume would entail additional operational cost. So Seeed giving it out for free is unprecedented even if the return is more PCBA sales.

As electronics engineer myself, I can’t stress enough the importance of knowing what’s wrong with my electronics design at the earliest stage. This task is not overwhelming if time is not a factor. But that’s hardly the case in the world of electronics design. This and the fact that outsourcing manufacturing have become cheaper over the years, more engineers have opted for these services.

Engineers have been employing Design for Manufacture (DFM) services in such instances. In fact, DFM is now considered a standard in PCB design manufacturing. However DFM has the disadvantage of having limited scope. For example, a typical DFM review only tells the client if the Gerber files are correct and translatable to an actual printed circuit board. It doesn’t include what a DFA review offers, an example of which, is presented in the next section.

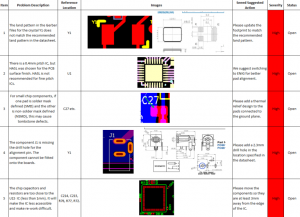

Consider the following errors included in an example DFA review:

• The BOM says 0402 but shows a 0603 land pattern – could result in tombstoning and consequently poor yield,

• Salvaging and re-working due to obscure polarity marks - leads to delays and wastage,

• Connector cut-outs or milling slots absent - if unseen, most likely the reason for starting the design over again.

Such errors will not have been included in a DFM review as they are beyond its scope.

No doubt, the most thorough PCB designer could have detected such errors. However, that would mean searching through datasheets and checking out the correct positions and pads of hundreds of electronic parts. But then again time is always a factor and such task will require tens of hours of work. So why not let others do the task? Seeed claims that their DFA engineers detect PCB design problems 80% every time!

According to Seeed, with problems detected during pre-production phase, the efficiency of production has greatly increased. This means delays have become less common and the overall production process is smooth. Prior to DFA, production delays are expected due to detected errors and the time it takes to contact customers and wait for their replies. Now, only the most complex of errors reach the production stage as most errors have already been solved during DFA in preproduction.

“Feedback regarding the DFA service has been immensely positive, so despite the large engineering cost, Seeed Studio delighted to offer this unique service for free for Seeed Fusion PCBA customers. We are confident you will not be disappointed,” claims a Seeed Studio representative.

Detecting design problems at the earliest stage is paramount. And with DFA review included in PCBA orders for free, I see no reason no to try out this service.

About Seeed Fusion

[box type="note" align="alignleft" class="" width=""]Power-Up your PCBA experience with Seeed Fusion. Utilize the unique online quoting platform that fetches complete turnkey PCB Assembly quotations, including parts procurement and PCB manufacture in seconds. Add functional testing or programming services, then await your personalized DFA report from their in-house engineers. Get a quotation now.

Seeed has accumulated over ten years of custom manufacturing experience, supply chain knowledge and hands-on paper to product expertise. They are also dedicated to providing the smartest, most convenient, feature-packed and value-for money service possible.

Crack open a bottle of peace-of-mind or brew some sereni-tea, and let Seeed handle the rest. Stay tuned next month for the next Power-Up PCBA update.[/box]