Top 5 Key Factors Affecting The Cost Of PCB

Guest Post from LHDPCB

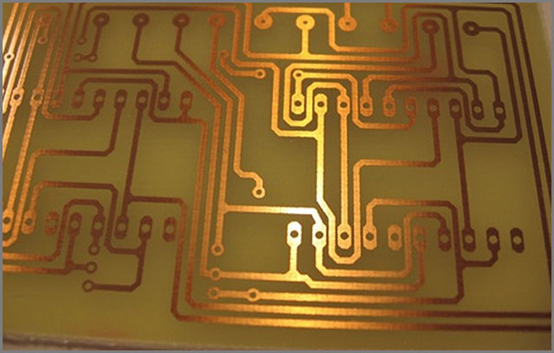

Many buyer have confuse about the price when they buy PCB from the PCB manufacturer , they want to know the factors which affecting the cost of PCB.

Let's learn something about the cost of the PCB.

1.Material-The 1st Key Factors

There are many material can be chosen for PCB, the base material have a big diversity in price and property.Selection criteria for materials used in fabricating PCBs depend on several application-based factors, defined mainly by frequency, speed of operation and maximum operating temperature. These factors include thermal stability, temperature-related reliability, temperature cycle reliability, heat transfer rate, time to delamination, and many others. In fact, the higher the frequency of operation or speed of the signals, the more important the choice of materials. For example, compared to conventional FR4 , polyimide increases cost by approximately three to five times, and PTFE-based microwave materials may inflate cost nearly 10 to 50 times.

The factors that can impact material selection include:

Thermal Reliability: Will the board be capable of performing under the range of temperatures expected for the tasks in question? Certain boards require materials of a higher thermal rating than standard boards.

- Temperature Reliability:Can the material withstand an expected range of atmospheric conditions within a controlled setting without overheating? PCBs intended for high-temperature working operations require materials that pass these tests.

- Heat Transfer: Will the board withstand high-intensity loads without transferring undue levels of heat to attached and adjacent components? The right material will need to pass this test for the uses in question.

- Signal Performance:Will the material facilitate uninterrupted electrical signals throughout each operating cycle of a given machine? Will the signal withstand a necessary range of temperatures and other environmental factors? These concerns are integral to the performance of a PCB.

- Mechanical Properties: Does the material have sufficient physical composition to withstand a plausible range of physical stresses? Can the board be pressed into a tight slot without cracking? Can it be dropped several feet without breaking? Any PCB ideal for sale will need to pass drop tests and other performance criteria.

As a rule of thumb, operations that involve higher frequencies require materials of a higher grade than standard FR4. As such, the materials used in a 5G PCB could be 50 times more costly than the materials used for the board in a calculator.

2.Surface Treatment

With the development of the PCB,there are many different surface treatment appeared.

Such as bare copper,rosin cover,OSP,HASL Tin lead,LFHASL,Immersion Tin,Immersion Silver ,ENIG,Flash Gold,ENEPIG,Golden Fingers,and some other complex (OSP+ENIG,ENIG+Golden Fingers,HASL+golden fingers,etc).

Some finishes boast higher grades and offer longer shelf life, thus adding to the overall cost of production. One of the more common and low-cost surface treatments is HASL, which offers good solderability but is rated unfavorably on other counts. ENIG, by comparison, scores favorably in most categories yet only commands a slight price difference.

Each of the surface treatment options offers unique features:

- HASL: Solderability,Cheap

- LFHASL:Solderability

- OSP:Solderability,Cheap,Strong combination

- IMM Ag: Solderability, Al wire bondable

- IMM Sn:Solderability

- ENIG:Solderability, Al wire bondable, contact surface

- ENEPIG: Solderability, Al wire bondable, contact surface

- Flash Gold: Solderability, Al/Au wire bondable, contact surface

3.Custom or Unique Specifications

Each PCB have different parameter when buyer send the orders.The price will higher if the board have a some holes less than 0.25mm.The price will increase if the holes' density is higher than normal,most factory will add $0.74/10k if the holes exceed 100k/m2.But LHD PCB will not add extra cost when the holes less than 200k/m2.

MIn track/space less than 4/4mil will lead the price increase ,and if the min track/space is 3/3mil will lead to many small factory can not make the board,so the buyer need to find a medium and large factory to make the board.LHD PCB can make the board with min 3/3mil,and we do not need extra cost when the min track/space is bigger than 3/4mil .

Some special requirement such as edge plating ,half PTH holes,blind and buried vias,control depth milling ,impedance control,halogen free,min copper on the wall of the holes, via on pads,carbon ink,peelable mask will increase the cost.

The different quality acceptance standard also have the different price.The common standard is IPC class 2,IPC class 3,Huawei company standard, MIL , ROHS , REACH GB/GJBstandard.Some PCB used for Automotive(ISO/TS16949),Aerospace(As9100), Medical(ISO 13485) also need extra cost,these board need special control and special report.

4.E-testing Cost And Mold Cost

A.E-testing Cost:Flying probe testing is used for samples(less than 3m2),this cost base on test points(if 1 unit board have 250 test points,the total test points will 250*100 if you want to buy 100pcs unit board),about $0.22/1k test points,and MOV is $15,and the flying probe testing cost will charge for each time; Fixture testing is used for big volum orders(bigger than 3m2),and the cost also base on test points,about $74/1k test points .but it only need once and do not need for repeat order,and it only calculate the test points for 1set or 1unit board.(if 1 unit board have 250 test points,and ship by 4up,the total test points is 1k,and the fixture testing cost is $74,the MOV for fixture testing is $74 also.);

B:Mold Cost:The factory use routing machine to make samples or small-middle series production,but the mold will be used to do outline for mass volum productions.The MOV for the mold is about $150,the price will higher if the outline is too complex.

5.Lead Time And Manufacturer

Some boards need urgent lead time,so the buyer need pay urgent fee to the manufacturer ; and sometimes the urgent cost is expensive than PCB cost if it is a sample order.For example,the price for double layer boards less than 0.3m2 is about $45,lead time 5days;when you want receive the board in 3days,the price will $74;and $90 ship in 2days.The urgent cost is more higher if the lead time is more short.

And the manufacturer is also a important factor for PCB cost,different have different price matrix ,every maunfacturer have different focus productions, and the price will have big difference when you send the same samples inquiry to a quick turn factory and a mass volum factory.

So chose a right manufacturer will reduce the cost and give you more help.

LHD PCB is your best choose,which is one of the world-leading high-precision double-layer and multi-layer printed circuit board manufacturer.and have earned our company an excellent reputation for consistent quality, on-time delivery, and exceptional service. We are proud of our advanced production and equipment testing, our development of new technology, and our implementation of multitiered quality and environmental management systems.Our products include (FPC ,HDI PCB ,rigid pcb ,rigid flex pcb ,metal core pcb and PCBA )

We have ISO9001 certification, UL certification, ISO14001 certification, and TS16949 automotive quality management system certification. All the circuit boards will be tested well before being shipped out.

We are here wait for your RFQs .

Email: info@lhd-pcb.com

Tel: +86-13715307049

Web: www.lhd-pcb.com