As an electronics manufacturer or buyer, then you have likely realized that Europe is taking sustainability seriously. The continent that introduced RoHS and REACH is implementing a new wave of environmental regulations, and this time, they are going deeper into supply chains than they have ever done before. To the companies which are dependent on the printed circuit boards, the question was not whether you are going to be affected on these changes or not, but whether you are ready when they happen.

The New Regulatory Landscape: What is really changing?

The most recent regulations have been a fundamental change to the European environmental policy though it has never been lacking in ambition. We are past the stage of merely prohibiting toxic materials and developing extensive systems that trace the products starting with raw materials, to their final disposition.

Corporate Sustainability Due Diligence Directive obliges companies to recognize and manage the environmental impacts of their whole value chain. That is, you must have visibility of your suppliers and likewise their suppliers and even the component manufacturers who are multiple tiers down the chain who you have never made direct contact with.

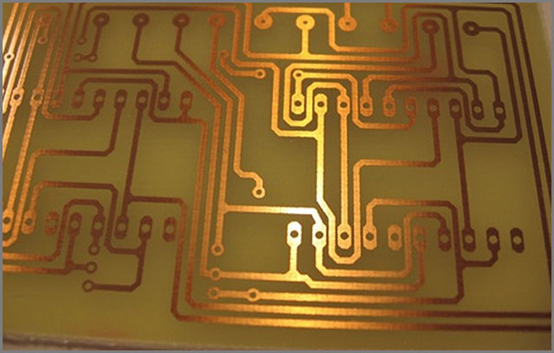

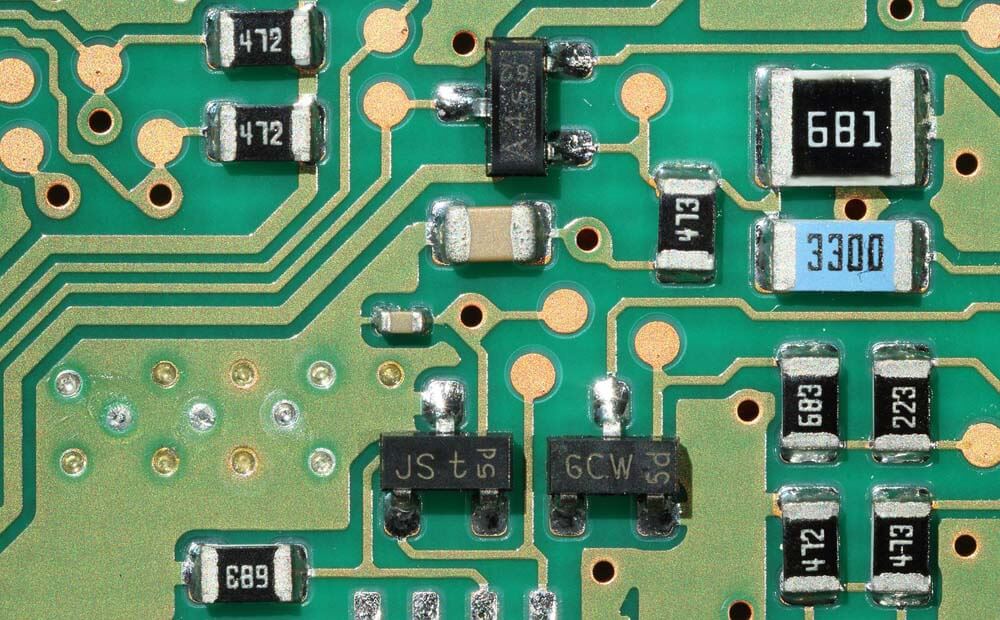

The new Ecodesign for Sustainable Products Regulation, is not only focused on energy efficiency but in addition to this, the document also addresses durability, repairability, and recyclability. For PCB manufacturers and their customers, this suggests the design of eco-friendly boards that can be easily taken apart and recycled, the use of materials with the least impact on the environment, and the documentation of the entire process with an extraordinary level of detail.

Many PCB applications, especially the portable electronics and electric vehicles, are also affected by the Battery Regulation of the EU, as it obligates their declaration on carbon footprint and raises the threshold of hazardous substances.

The reason why your existing strategy is not sufficient.

This is where most companies reach a dead end. You could be RoHS compliant and your REACH declarations current but these new laws are on a totally other plane. Conventional compliance used to be based on passing certain exams or achieving certain levels. The new wave requires continuous due diligence, supply chain transparency and lifecycle thinking.

Not knowing your boards are lead-free is inadequate but what you should have is the carbon footprint of the boards you use, the conditions that workers have to work under at the factories where they are manufactured, and whether the materials are recoverable at the end-of-life. This presents specific difficulties to the companies which operate with global supply chains, in which case, geographic distance and cultural context complicate obtaining the detailed information that these regulations demand.

The European Competitiveness: Proximity and Compliance.

It is here that regional supply chains begin to become more attractive. The benefits of collaborating with a PCB manufacturer in France exceed the reduced shipping time. The manufacturers in Europe are already working through these regulations to have their own operations going on, which means that they know the documentation you then need, the standards you should meet, and the reporting obligations you will encounter.

Consider the complexity of carbon footprint reporting with the new rules. A local manufacturer is far more easily audited, claims checked and improvements strived through. You will have the opportunity to visit facilities, meet with environmental compliance teams, and develop the relationships that will make the ongoing due diligence appear to be a manageable, not an overwhelming task.

European manufacturers aren't just compliant because they have to be—they're often at the forefront of sustainable manufacturing practices because they've been operating in this strict regulatory environment for years. They've already invested in cleaner processes, better waste management, and supply chain transparency tools that many global competitors are only beginning to adopt.

Creating a Vigorous and Adherent Supply Chain.

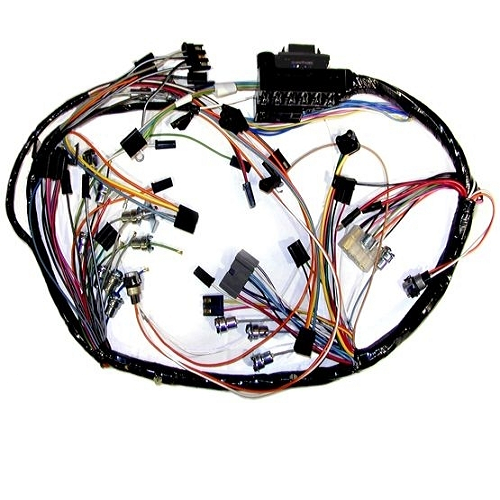

So what are you supposed to do? Begin with an extensive supply chain mapping process. You should not only be familiar with your local PCB supplier, but how they acquire their material, how they process it, and what their suppliers would appear like. This visibility is becoming non-negotiable.

Create effective channels of communication with your suppliers as regards environmental needs. It is not a single discussion but a continuous process of dialogue regarding changes in regulations, quality improvement measures, and possible risks. The optimum supplier relations are collaboration in which both parties cooperate to be ahead of the compliance regulations.

You should also think about diversifying your supply base and have more European options. One of the PCB fabrication company in Spain may be competitive in pricing and has the proximity and compliance benefits that we have talked of. In the same way, a PCB production company in Portugal will be able to provide quality products already with built-in regulatory compliance, which will have a smoother process of compliance.

Documentation is much needed although it may seem boring. Implement mechanisms of gathering and sorting compliance certificates, carbon footprint records, material pronouncements, and audit reports. When you are questioned by the regulator or customers to provide evidence of due diligence, you desire to have a detailed documentation.

The Competitive Advantage of first Mover.

Conformity is not all about punishment, it is now a competitive advantage. Customers are increasingly choosing suppliers based on environmental credentials, and procurement departments are adding sustainability requirements to their RFQs. If you can demonstrate a robust, compliant, and transparent supply chain, you're winning business.

Organizations which pay close attention to these regulations tend to find gaps to improve where they would not have otherwise found. When collaborating with the German PCB production specialists, e.g., one can frequently find a new solution to sustainable manufacturing that can not only help you to leave a smaller imprint on the environment but also enhance your productivity.

First movers also have easy access to the relationships with regulators and simpler inspections. When the government understands that you are not neglecting these requirements, they are less inclined to examine you carefully and have rigorous enforcement measures.

Looking Ahead: The Regulations Aren’t Slowing Down.

And in case you are hoping that this wave of regulation will hit its peak and settle down, consider otherwise. Europe has taken serious climate commitments, and supply chain transparency is one of the foundations of their fulfillment. Regulations are on the rise and they are expected to be more demanding.

It is wise to see compliance as an investment in long-term viability rather than as a burden. A supply chain that is capable of changing with the times and regulations, an honest display of sustainability commitment, and the creation of systems and relations that make compliance easy—these are the areas where companies get the most return over the years.

Conclusion: Time to Act

The European green regulations can be viewed as a paradigm shift of our thinking in regards to manufacturing, supply chains and environmental responsibility. They are challenging and intricate, and those companies that change fast will offer valuable benefits compared to those that wait.

Have a close look at your PCB supply chain. Is your visibility that these regulations demand? Are your suppliers prepared? Are you able to record your due diligence? It is actually good news that the answers make you feel uncomfortable because it means that you are already determining the problems and there is still time to fix them.

What are you doing to prepare your supply chain to these new regulations? Share your experiences or write comments, we are all going through this switch together and your experiences may perhaps guide others in identifying superior ways.