Locating an ideal international PCB partner would be like locating a needle in a haystack. There are dozens of manufacturers around the world all of whom say that they are quality, fast and affordable, but how can you expect a person to see the truly great one that is more than a simple mediocre? You need to pick the right PCB partner when you are releasing your initial hardware product or you are an experienced engineer aiming to streamline your supply chain: the selection of a PCB partner is one of the most important choices you will make.

The good news? Having the proper attitude and the expertise you can find a partner who not only matches your technical specifications but will be a real partner in actualizing your imagination. How do we go about this big decision with ease?

Getting Your Project Requirements Clear Working out.

You will be better off stepping back before you even begin to view manufacturer websites or ask them to give you quotes, and ensuring that you get crystal clear in what your project actually requires. This may be a given fact but most of the companies have a quick decision to make on where to partner without clearly doing a mapping of what they need only to realize later in the future that they got into an expensive mismatch.

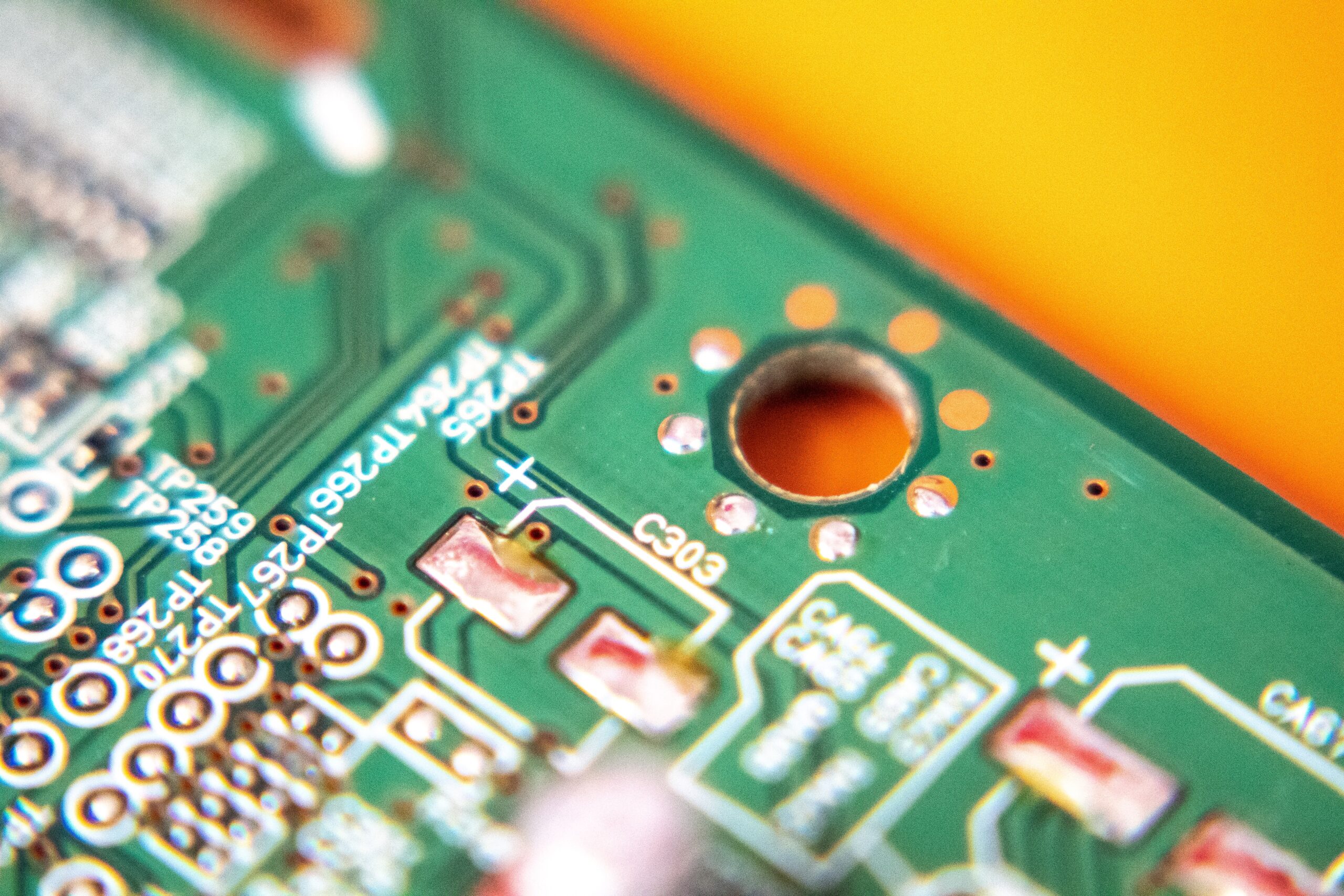

Take into account the design complexity. Is it standard FR-4 material and plain two-layer boards that you are using, or are your requirements high-frequency material, flex PCBs, or multilayer stackups? Technical savvy of your design will reduce the list of potential partners drastically. When dealing with a specialized need, seek out custom PCB design and assembly experts that know how to make an item manufacturable as well as have a design depth that is capable of streamlining your product to manufacturability.

Think about volume too. A prototype master and low-run producer may not cope with the logistics and economics of mass production. On the other hand, a factory that is designed to produce large volumes might not offer personalized service and flexibility required during the development process.

Don’t forget about certification requirements. If your PCBs will go into medical devices, aerospace applications, or automotive systems, you'll need partners with relevant certifications like ISO 13485, AS9100, or IATF 16949. These aren't just nice-to-haves; they're often legal requirements that can make or break your market entry.

Assessing Technical Strengths and Fine Art.

After you have the idea of what you need, it is time to assess the ability of your partners if they can deliver it or not. Begin by looking into detail at their technical capabilities. Ask them to provide their capability matrix and that should include all the minimum trace widths and spacing as well as the number of layers, types of materials they can work with and the types of surface finishes.

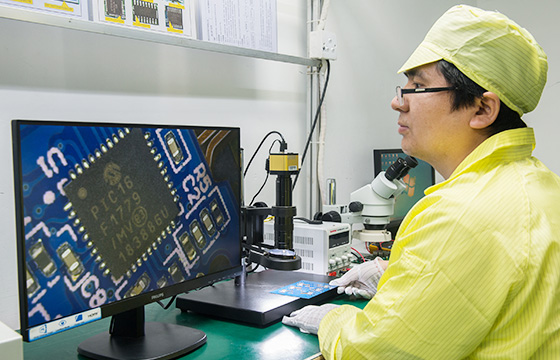

Always keep their quality control processes in view. A reliable producer must be clear about their checking methods, which include not only automated optical inspection and X-ray inspection but also electrical tests and impedance control. Inquire about their rejection rates and what their normal yield percentages are for boards that are like yours.

There is no need to be afraid to demand samples of past work or references.

Geographic and Logistical Factors to Consider.

Geography is not irrelevant as you may be thinking, or necessarily in the ways you may think. Although the PCB manufacturing industry has always been dominated by Asia, the situation has grown more varied, with new manufacturing centers that present significant advantages.

Look at such areas as Eastern Europe that have set up advanced production capacities with the advantage of geographic position to European markets. A local custom PCB manufacturer in Poland could be the right mix of quality, affordable rates and shorter delivery times to the European market, and it could be much easier to communicate during European busies hours and does not overlap with Asian time zones as well.

On the same note, the manufacturing excellence in the Southeast Asian countries is still being streamlined. PCB assembly company in Thailand could be the best in terms of value to companies that are seeking good assembly services with high quality in control, especially in the aspect of medium volume production runs. The electronic manufacturing industry of Thailand has seen massive investment in current equipment and training in technical aspects.

To individuals researching the prospects of various sourcing alternatives, PCB manufacturing services in Turkey provide an intriguing compromise, with low pricing and a well-chosen location between Europe, Asia, and the Middle East. The increasing technology base in Turkey has invested heavily in the manufacturing infrastructure of electronics.

The trick is to align geographic factors to project priorities. When developing, cost savings over a long distance might be minor compared to a partner in a time zone that is closer to you and has shorter shipping distances.

Evaluating Communication and Customer Service.

Here's a point that doesn't show up on specification sheets but is of tremendous importance: the quality of communication. Even the most advanced technical features might be of no use if the communication with your manufacturing partner is not effective.

When interacting with them first, notice how quickly they respond, how good their responses are and whether they ask clarifying questions or not. Not only do they appear to be interested in hearing about your project, but they are also merely attempting to make a sale? Does their team speak the language you like well especially when talking about technical aspects?

Find associates who assign you a special account manager or engineer who gets to know your needs. This continuity of a relationship minimizes errors, accelerates solution to a problem and makes the whole manufacturing process simpler.

Assessment of Pricing Designs and Aggregate Costs.

Price matters, but it's rarely as straightforward as comparing numbers on quotes. Intelligent purchasers consider total cost of ownership and not unit price. A quote offered by one manufacturer may appear higher but he or she may charge set up fees, testing, and shipping whereas the lower price may not cover these factors in another manufacturer.

Beware of the prices that are too good to be true since they normally are. Unrealistically low quotes might indicate that the quality control would be cut to corners, the materials may be of low quality or that there are other charges that emerge in the future. Take into account terms of payment, stability of currencies and their provision of payment options to regular customers.

Making Your Final Decision

You now need a shortlist of candidates after examining technical abilities, quality of communication, logistics and pricing. It is a good idea to start with some pilot project or a prototype run.

In this trial stage, criticize it all: How well did they work to your specifications? Did they match their standards of quality? What was the quality of their communication during the process? Did they achieve set schedules?

After you have chosen your partner, invest in a good relationship. Prepare your product roadmap, Share your roadmap with them so that they can plan capacity and possibly better pricing. The most successful international PCB relationships become more of a partnership where you have a manufacturer who is considered to be part of your engineering team.

Prepared to Find your Ideal PCB Partners?

To identify the most appropriate international PCB partner, one needs to conduct thorough research, communicate effectively, and conduct a systematic assessment. Through a comprehensive knowledge of your needs, critical evaluation of technical capacities, and consideration of logistic aspects, and emphasis on effective communication, you can be able to find a manufacturer partner that plays an active role in ensuring that your product succeeds.

Which have been the most critical factors in your PCB manufacturing partners search? Write about your experiences in the comments!