Controlling a Servo Motor with BoneScript

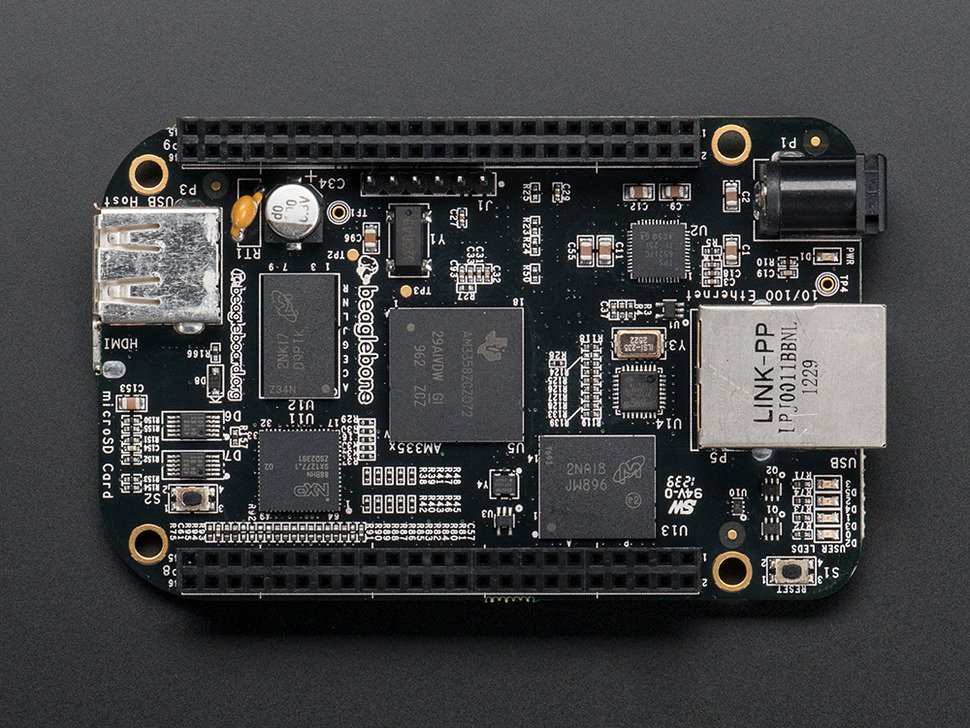

Using the Beaglebone Black's PWM

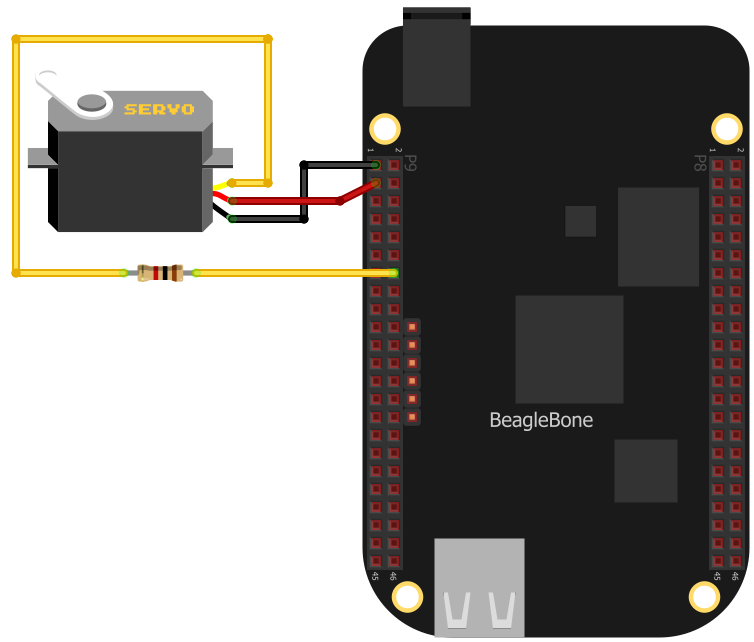

Bonescript also includes an analogWrite function which utilizes the 8 PWM pins of the Beaglebone Black. As you might already know, PWM allows us to control a servo motor. The analogWrite function accepts the pin name, duty cycle, frequency, and callback function as parameters. The duty cycle value can be between 0 and 1 while the frequency is in Hertz. Here’s an example:

var b = require('bonescript');

b.pinMode('P9_14', b.OUTPUT);

b.analogWrite('P9_14', 0.7, 2000.0, printStatus);

function printStatus(x) {

console.log('value = ' + x.value);

}

Here, the PWM pin used is P9_14, the duty cycle is 0.7 or 70% and the frequency is 2 kHz. The analogWrite function returns true if successful and false on failure. In the example above, x.value would have a value of “1” if the call to analogWrite is successful.

A servomotor needs a 1.5-millisecond pulse width for its arm to be in the center position. A 1.5 ms pulse width on a 500 Hz frequency is around 75% of the duty cycle. Thus, this script will position the arm in the center position:

var b = require('bonescript');

b.pinMode('P9_14', b.OUTPUT);

b.analogWrite('P9_14', 0.75, 500.0, printStatus);

function printStatus(x) {

console.log('x.value = ' + x.value)

}

Here's a script that "sweeps" the servomotor arm to and from its two extreme positions:

var b = require('bonescript');

var increment = 0.1;

b.pinMode("P9_14", b.OUTPUT);

updatePos();

function loop() {

b.analogWrite("P9_14", duty_cycle, 500, updatePos);

}

function updatePos() {

duty_cycle = duty_cycle + increment;

if(duty_cycle < 0.5) {

duty_cycle = 0.5;

increment = -increment;

} else if(duty_cycle > 1) {

duty_cycle = 1;

increment = -increment;

}

// loop every 200ms

setTimeout(loop, 200);

}