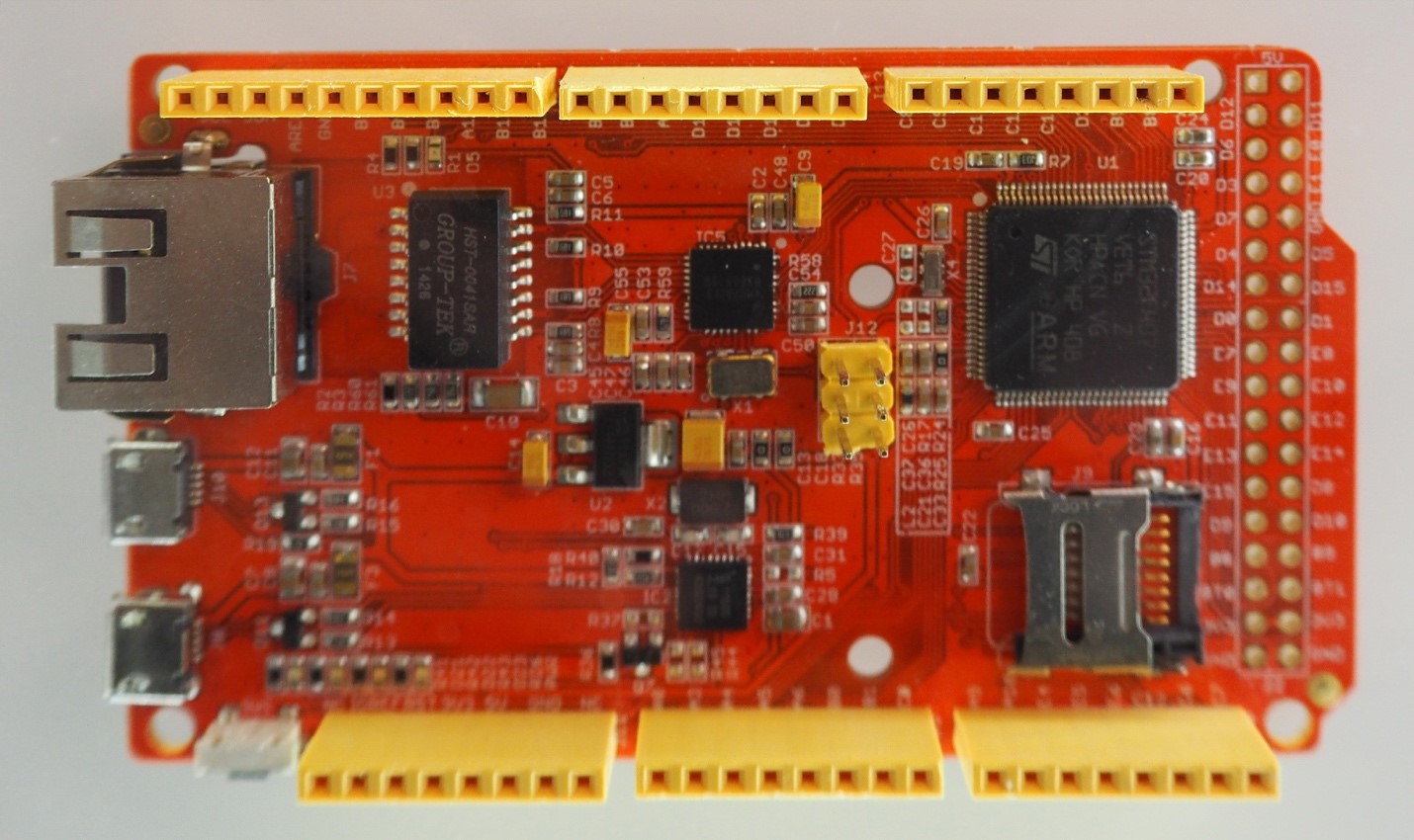

Have you ever spent hours and hours creating the perfect circuit, only to have it fail on the test bench for no clear reason? The problem could be right in front of you: the copper lines on your printed circuit board (PCB) are too wide. What is a PCB trace? It's not just a wire in the world of radio frequency (RF) and high-speed digital electronics. The electrical qualities of this complicated part can make or break the performance of your design. It is very important to get the trace width right for signal integrity, which is the quality of the signal as it moves from a source to a receiver. Understand why trace width is important and how to find it without getting bogged down in complicated physics with this help.

Why Does Trace Width Matter So Much?

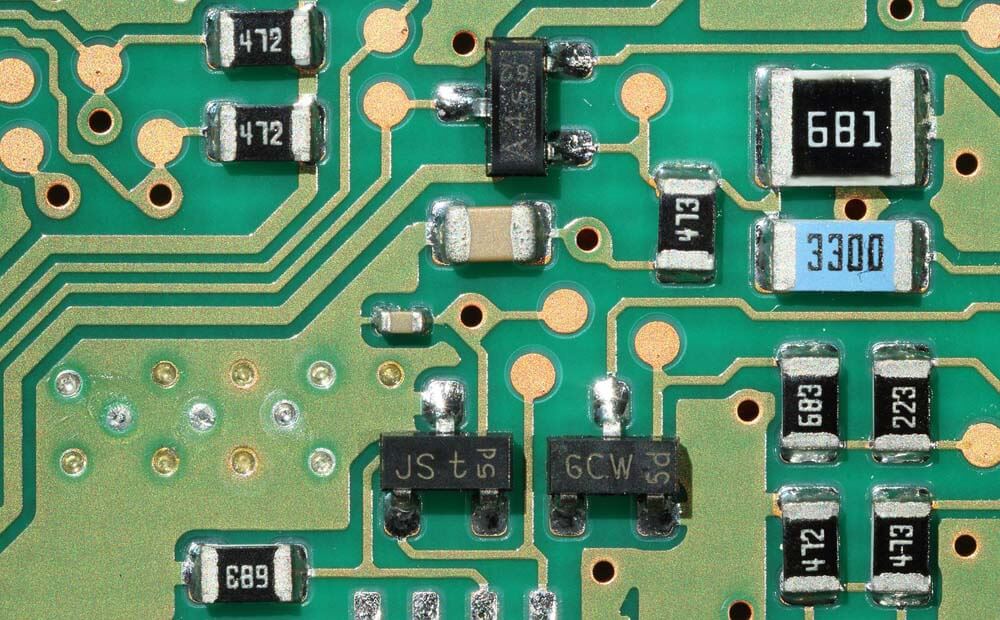

It is generally thought that a PCB trace acts like a perfect conductor below a certain point. But as the signal speed goes up, the trace starts to act like a transmission line. A signal transmission transmission line has its own characteristic resistance, which tells you how it reacts to an electrical signal moving through it.

Imagine running water through a yard hose that gets narrow and then gets wider again: At each change in width, some of the water splashes back to make the flow rough. When a signal goes through a resistance change in an electrical circuit, the same thing happens: Some of the energy is sent back to the source, which makes noise, try rings, and other distortions that could actually mess up the data. So, to stop these kinds of reflections from happening, it is emphasized how important it is to keep the impedance consistently managed. When it comes to resistance, one of the most important things is the width of your trace. You can make your signal path smooth and free of splashes by being determined and careful with it.

The Key Ingredients for Your Calculation

Figuring out the right width for a trace is not just a wild guess; it's a science that depends on how your PCB stacks up physically. To find the right width in this case, you need three main factors, which your PCB manufacturer will be happy to give you.

One is your board's dielectric constant, which is written as (Er). This number shows how the shielding material (substrate) between the copper layers changes the electric field. Most of the time, FR-4 is used. Its dielectric constant is about 4.5, but it can change.

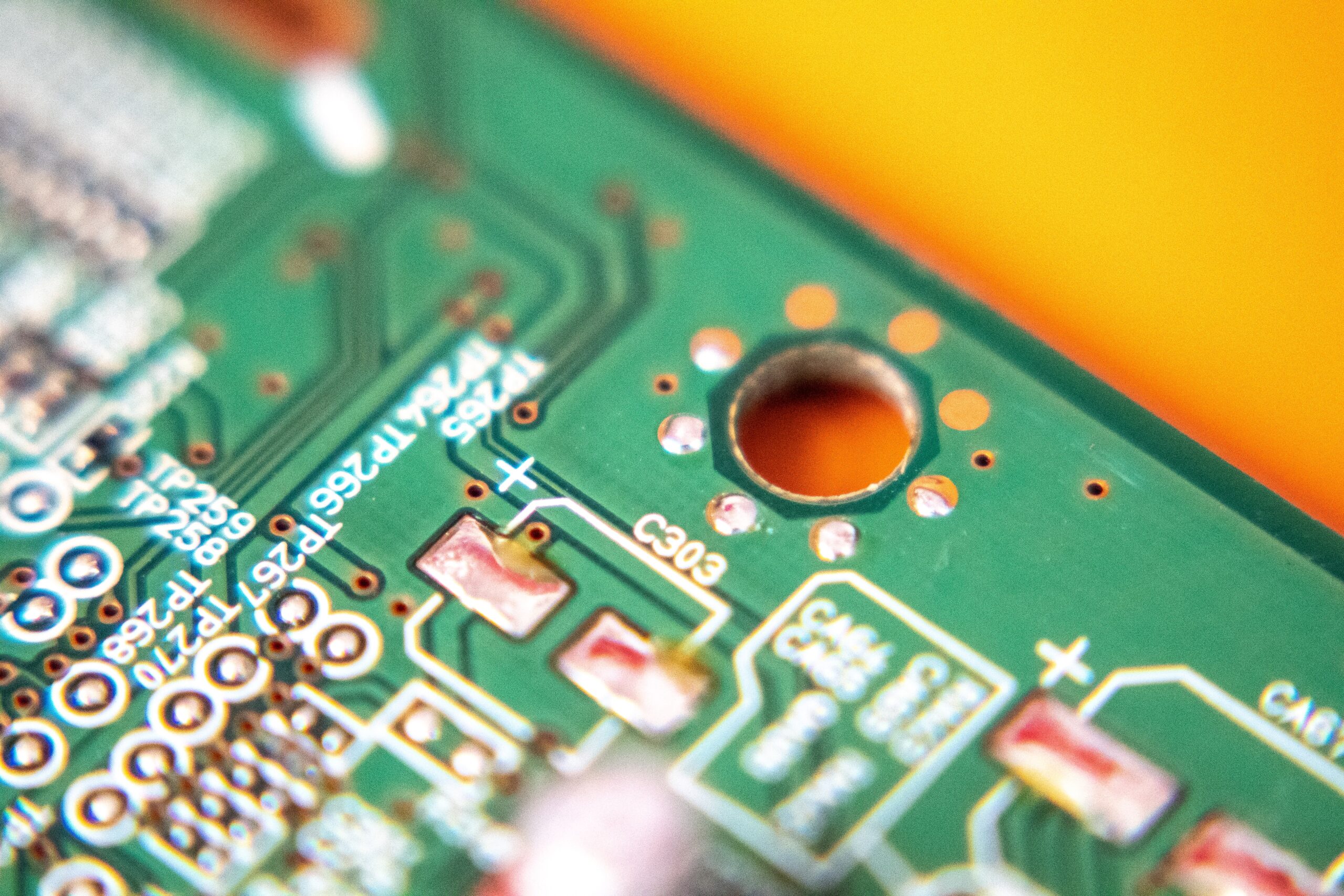

The second thing you need to know is the dielectric material's height (H). This is how far your signal trace is from its reference plane, which is usually a solid ground or power plane. If a trace is close to its reference line, its impedance will be low.

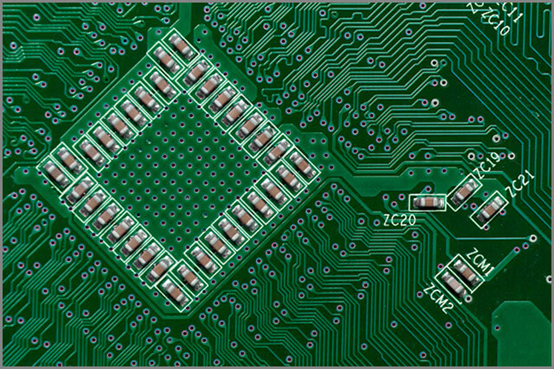

Lastly, you need to know the trace's thickness (T), which is based on the weight of the copper (1 oz of copper is about 1.37 mils, or 35 micrometres thick). For any trace thickness, the thicker the copper, the less impedance it has. The last piece of the puzzle is the trace width (W), which is made up of these three parts: (Er), (H), and (T).

Your Toolkit: From Complex Math to Simple Calculators

Using these physical qualities to figure out impedance is not easy. You have to use natural logarithms and complex geometries in your formulas. You don't have to solve them by hand very often, which is good. The tech community has made great tools that can do most of the work for you.

Any PCB creator needs to have an electrical impedance calculator on hand. With the dielectric constant, trace thickness, and height of your board as input, these tools help you figure out the trace shape you need to reach a certain impedance. That's why the goal impedance for many single-ended signals, like those used in logic or RF, is usually 50 ohms (50 Ω). You could aim for 90 or 100 ohms (90 Ω or 100 Ω). for differential pairs like USB or Ethernet.

For more detailed help, a PCB trace width calculator is made just for this. It will give you the exact trace width you need after you enter your goal impedance and the properties of your PCB stackup. You can get these tools online, as stand-alone programmes, or as parts of more advanced EDA (Electronic Design Automation) software. They are your best friend when you want to make sure that signals work right from the beginning of the planning process.

A Quick Practical Walkthrough

Let's move on to the very real-life case. Let's say you are making a board with a 50 $\Omega$ signal trace.

- Figure out your goal: The average impedance that you want to reach is 50 Ω.

- Get Your Stackup Info: You then contact your PCB manufacturer and find that in his 4-layer standard process, the dielectric is FR-4 having a Dielectric constant of 4.2. The trace will be put on top, with 1 oz copper pour (1.37 mils thick), and the distance to the ground plane on layer-2 is 10 mils.

- Plug and Chug: If you want to find the trace width online, enter these numbers: goal impedance = 50; dielectric constant = 4.2; dielectric height = 10 mils; trace thickness = 1.37 mils.

- Find Out the Answer: The calculator arrives at a calculation and spells out that the trace width needed to be about 18.5 mils to achieve your target impedance. Now, you can implement this number for routing in your design software for critical traces.

This method is a good step away from guesswork and towards an engineering-based answer that almost guarantees the circuit will work. Remember to keep in touch with your fab house, because differences in materials and manufacturing limits can change the end result.

Conclusion

Learning how to figure out PCB trace width is an important step on the way to becoming a good hardware designer. It is the key to controlling signal echoes and making sure that your high-speed signals get where they're going without any problems. It is possible to build strong, reliable, and high-performing electronics if you know how the physical geometry of a trace affects its electrical impedance and use the powerful calculators that are available to you.