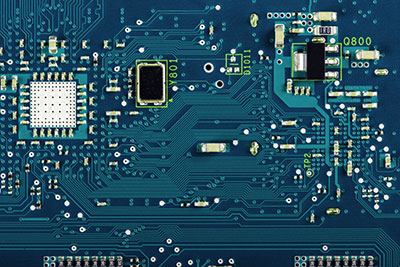

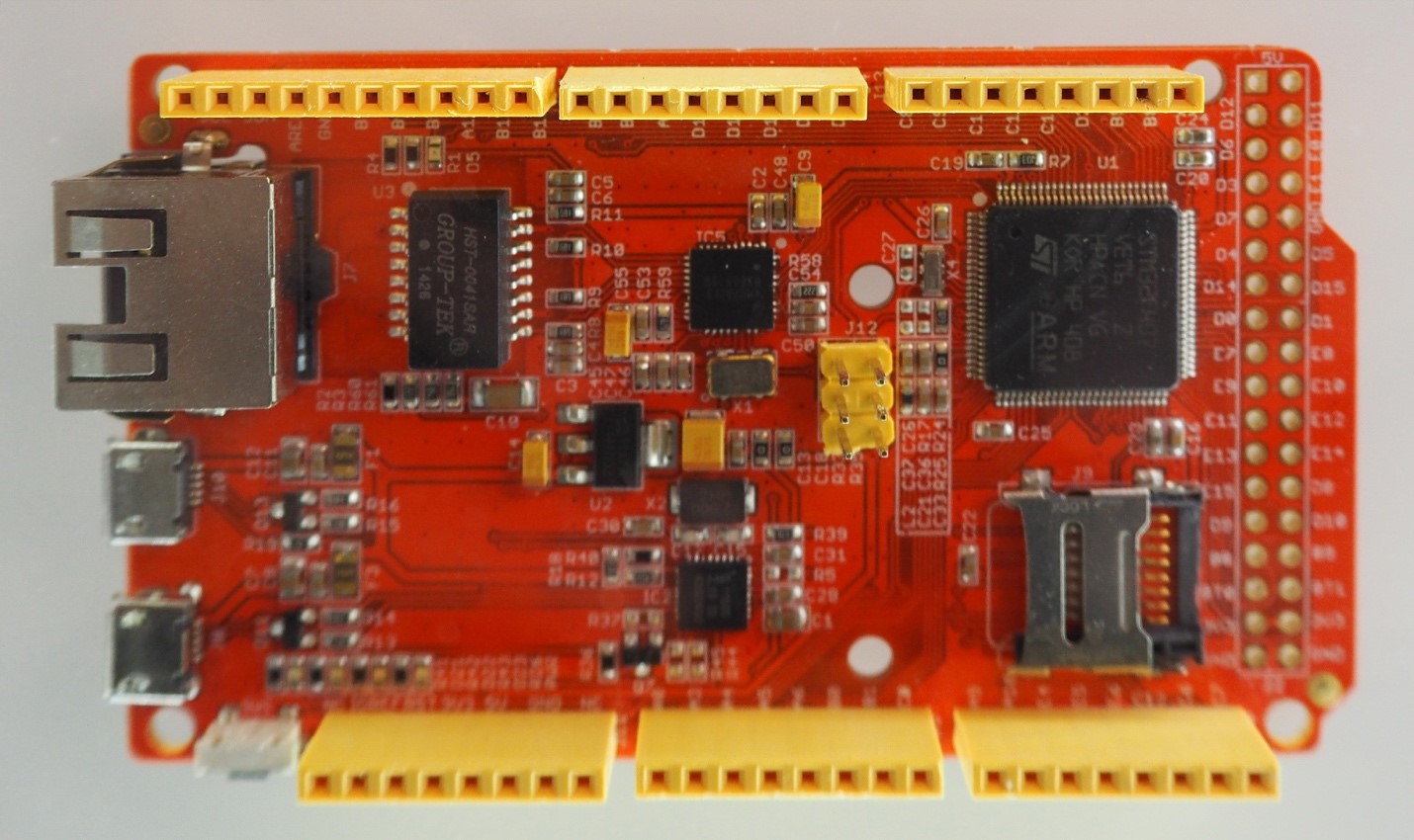

Have you ever wondered why your smartphone works, your laptop performs, or your smart home devices talk in unison, it is very possible that you have found the answer in something that you rarely see: the printed circuit board, or PCB. These complex green boards are the unrecognized heroes of the new-age electronics, which forms the basis on which just about every electronic appliance is anchored. However, making these necessary elements is not as easy as hooking a few wires together-it is a complex process, which starts with a thorough design and ends with mass production.

What is So Critical about PCB Design? To understand the Foundation.

Consider a PCB to be the nervous system of an electronic device. As your nerves carry messages all over your body, a PCB carries electric messages between components which makes everything work in perfect harmony. It is during the design phase that all the magic is created and getting it right at the very start can spell out the difference between a successful product and an expensive failure.

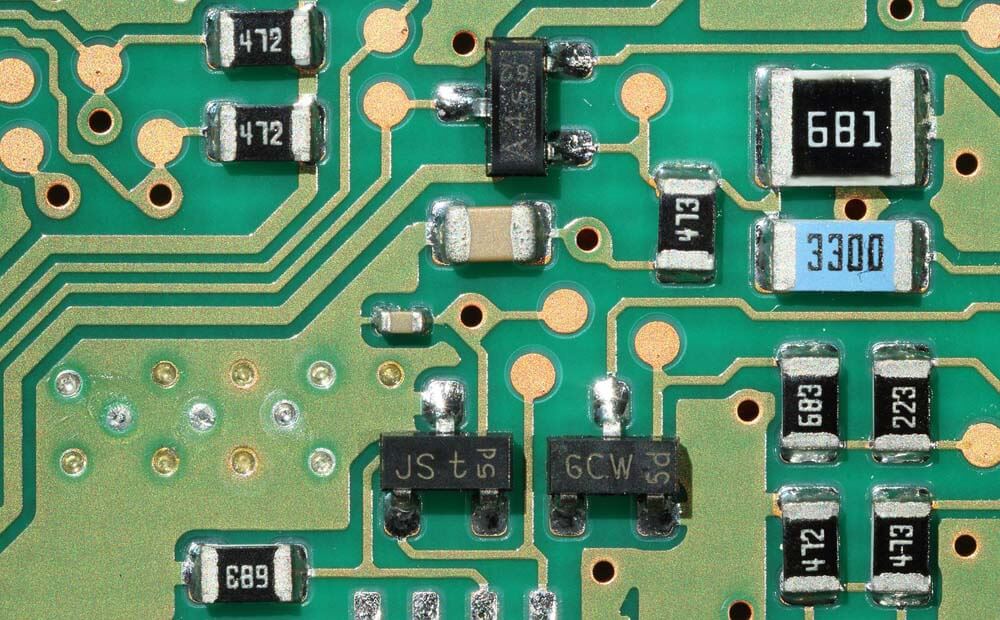

The current design of PCB is a big improvement when compared to the plain one-layered boards that were used in the old days. The current designs make use of multiple layers, at times up to ten or more layers in complex designs. The purpose of each layer is defined, which is either carrying power, routing signals, or a ground plane in which the electrical stability is secured. Such designs are not only complex but also need creativity and problem solving skills.

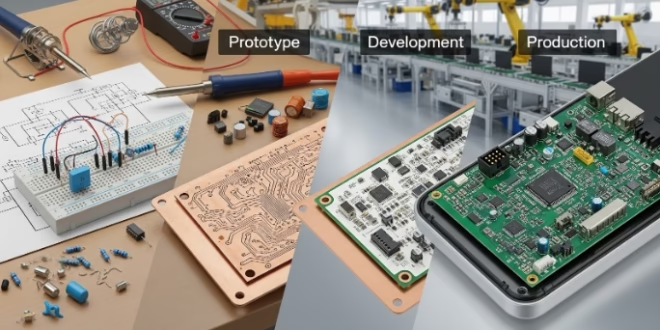

Concept to Prototype The Design Process Revealed.

From having an idea to making a prototype is a process comprising several steps. The first step is drawing the schematic, which is a blueprint showing connections among all the components. Once the schematic is complete, the next step is to take it into the physical world and lay out the board.

At that point, a compromise becomes necessary depending on the size, performance, and manufacturability. Components must be placed with efficient use of space and ease of assembly in mind. From the perspective of high-speed traces, they should be routed in such a way as to interfere as little as possible; power paths should have sufficient current without causing voltage drops; and in terms of heat dissipation, it should be fast enough to incur any damage to the components.

Modern design software brings forth features like auto-routing, design rule checks, and 3D visualization that make this process simpler. Designers continually aid in knowing when to trust computer and when to step in manually. They realize that sometimes a graphically correct layout is not the best electrical design, and balancing both is necessary for success.

After the preliminary design is done, now it is time to have the prototype phase. This is where theory is met by the reality and usually where the concealed problems are revealed. Prototyping can be aided with professional PCB manufacturing services which could streamline the process much as the experienced manufacturers may notice the possible problems in production in its early stages before it escalates into a costly problem.

Experiment, Revision and Perfecting: The Way to the Unattainable.

The creation of the first prototype is a thrilling part of the story, yet it hardly ends there. It is at this point that rigorous testing is required. Designers put prototypes to test, and they ensure that all the basic functions of the product are met and also the product functions properly even in extreme conditions. Does the board work as intended? Are there any signal integrity issues? Does it generate too much heat?

Design revisions are common answers to such questions. Maybe one of the components should be repositioned to allow better heat dissipation, or trace impedances should be changed to suit signal quality. This repetition may appear tiresome, but it is extremely essential. With every application, the design gets nearer to production safety and all possible issues, which can haunt the product after reaching the customers, are removed.

Modern electronics often require more than just PCBs. Many devices require interconnect solutions, and this is where the skills in wire harness design and manufacturing become useful. A wire harness gives organization and protection to the numerous wires and cables that are going between the different PCBs or components in a device. By coordinating PCB design with these interconnect solutions from the early stages, seamless integration is ensured and costly redesigns later can be prevented.

Scaling Up: Moving out of Prototyping into Production.

The transition between a working prototype and full-scale production is one of the most important steps in the development of a product. What would work at all using a few prototypes may not be viable when it comes to making thousands or millions of products. It is here that design of manufacturability comes into play.

Production-ready designs consider factors that prototypes might overlook. Is it possible to assemble the board by automated equipment? Do the components have many suppliers, or would problems in the supply chain stop the production? Does it have enough tolerance to normal manufacturing variations?

Partnering with providers offering custom PCB assembly solutions during this transition phase can be invaluable. They also introduce manufacturing skills that support design skills and therefore aid in identifying possible bottlenecks during the design stage before production sets in. They may propose substitutes of components whose functionality is identical but more readily available or propose layout modifications that increase the yield rate of assembly.

The sophistication of the contemporary devices can go more than PCBs and wire harness. Numerous products involves specialized cable assemblies to either connect internal parts or to connect to external devices. When you include a custom cable assembly services in your production plan, these important interconnects are also treated with as much care in regard to quality and reliability as the PCBs themselves.

The Significance of Strategy Alliances.

There is no single company working in a vacuum, and the successful manufacturing of electronics is usually associated with interworking of different specialties. Your team may be the best in PCB design and system architecture; however, collaboration with other professionals in different fields can increase the quality and reliability of your product.

An example of this is the case with a custom wire assembly company that is aware of the particular needs of your application creating more dependable connections and providing simpler serviceability. These experts have a wealth of experience in interconnect issues in a variety of fields, and in many cases, they can offer you some solutions that you have not thought of.

What lies ahead: PCB Design in the Future.

PCB design is evolving rapidly. Flexible and rigid-flex PCBs are enabling new form factors which previously were not possible with rigid boards. Advanced materials bring high-frequency performance to the table, whereas embedded components and integrated passive devices aid in miniaturization.

Manufacturing, too, is tilting towards advanced, additive techniques, with the advantages of decreased prototyping time and greater design freedom. However, with these innovations, new challenges are posed.

All such changes do hold one truth constant: design quality and thoroughness. No technology can fix the wrong first choices. The greatest successes will always come to skilled designers working with the appropriate tools and partnerships to address real needs.

Closure: Your Design to Reality.

Production of modern electronics is a complicated process, that needs skills in various fields. Design, prototyping, testing, and other stages, all the way to production result as a continuation of the earlier stage. It does not only demand technical expertise but also tactical thinking, eye-hand skills and the intelligence to outsource tasks where your capabilities lack.

Whether you're developing your first electronic product or refining your hundredth, remember that great PCB design is both an art and a science. It requires balancing competing demands, making informed tradeoffs, and always keeping the end goal in sight: creating products that work reliably, manufacture efficiently, and delight customers.

What is your PCB designing and PCB manufacturing experience? Did you make it through prototype to production? Comment below with your ideas and concerns, we just want to hear your story!