Signal integrity and power integrity are critical factors in the fabrication and design of printed circuit boards (PCBs). These factors play a significant role in ensuring that the PCBs function as intended, without interference or noise that could degrade performance or even cause the circuit to fail.

This article highlights signal and power integrity's importance in PCB fabrication and design.

Signal Integrity

Signal integrity is concerned with the quality and reliability of the signals that are transmitted across the PCB. Signal integrity problems can occur due to a variety of factors, including noise, interference, crosstalk, and impedance mismatches. These problems can cause signal degradation, leading to errors, reduced performance, or complete circuit failure.

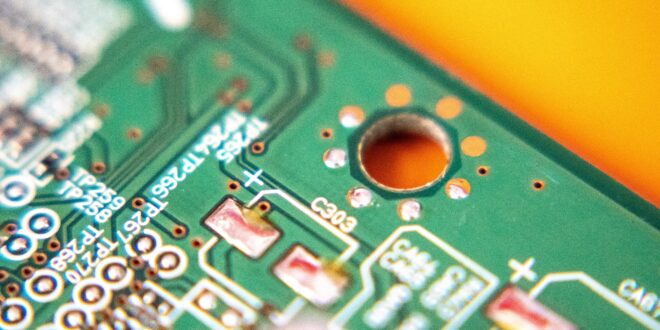

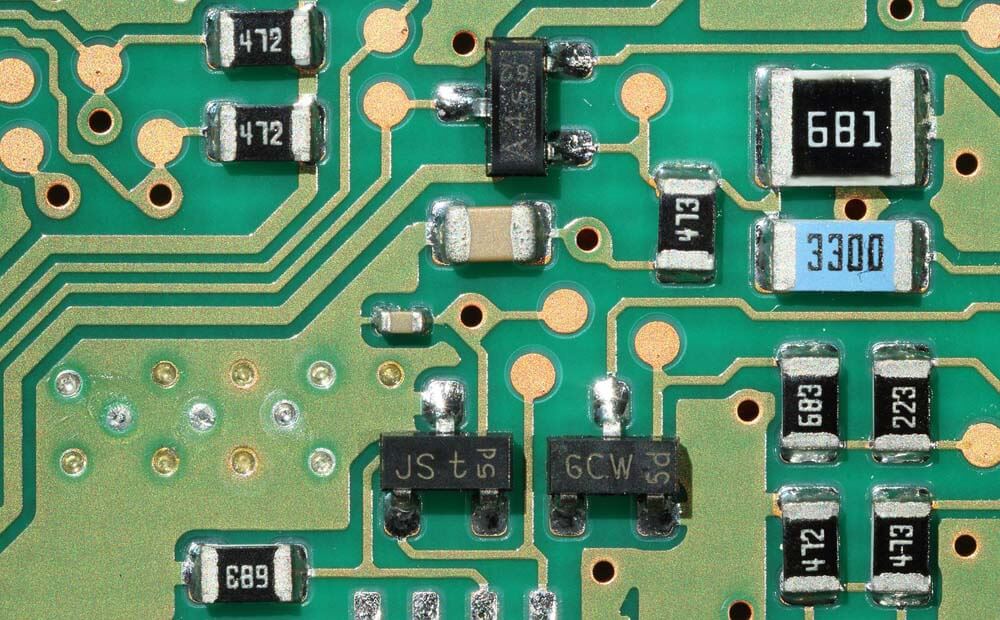

To ensure good signal integrity in PCB design and fabrication, it is essential to consider factors such as trace routing, signal termination, ground planes, and decoupling capacitors. Trace routing refers to the layout and routing of signal traces on the PCB. Having good trace routing practices can help reduce signal interference, minimize crosstalk, and ensure proper impedance matching.

Signal termination refers to the techniques used to end a signal to prevent reflections and signal loss properly. Ground planes are used to provide a stable reference voltage and reduce noise on the PCB. Decoupling capacitors can filter out high-frequency noise from power supplies.

Power Integrity

Meanwhile, power integrity focuses on the quality and reliability of the power supply to the printed circuit board. Power integrity problems can occur due to several factors, such as voltage drops, noise, and interference. These problems can cause improper circuit operation, leading to errors or complete failure.

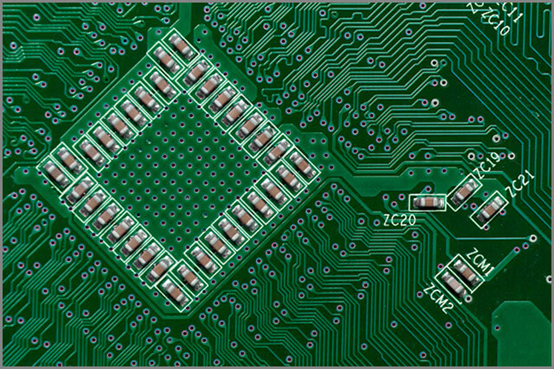

Ensure good power integrity in PCB design and fabrication, by considering important factors such as power distribution, decoupling capacitors, and power planes.

Power distribution refers to routing power traces on the PCB, and maintaining a good allocation can help reduce voltage drops and minimize noise on the PCB. Decoupling capacitors, on the other hand, are handy when it comes to filtering out high-frequency noise from power supplies.

Power planes are a key element in achieving a stable reference voltage and reducing noise on the PCB. Good power plane design involves carefully considering the voltage and current requirements of the circuit and ensuring that the power plane's design meets these requirements.

In summary, signal integrity and power integrity are critical factors in print circuit board fabrication and design. Good signal and power integrity practices can help ensure that the PCB functions as intended, without interference or noise that could degrade performance or cause the circuit to fail.

Choosing a PCB Manufacturing Service Provider

If you're considering designing or fabricating a PCB, it's crucial to consult or partner with a reliable and experienced PCB manufacturing service provider. ELE PCB is a reputable company that provides high-quality PCB materials and assembly services. Their roster of industrial-grade products and services is widely renowned as they are designed to meet the standards and requirements of a wide range of clienteles, from non-professionals to large corporations.